Turbine Filter Analysis – Follow-up Analysis Turbine

Problem Summary:

Filter media was obtained from Turbine #2, during the opening of the filter – a lot of metal debris was observed. The filter media was sent in for testing to determine the source of the presence of metals found along to determine the source of the wear metals observed.

Turbine Filter Debris Analysis: 24090089

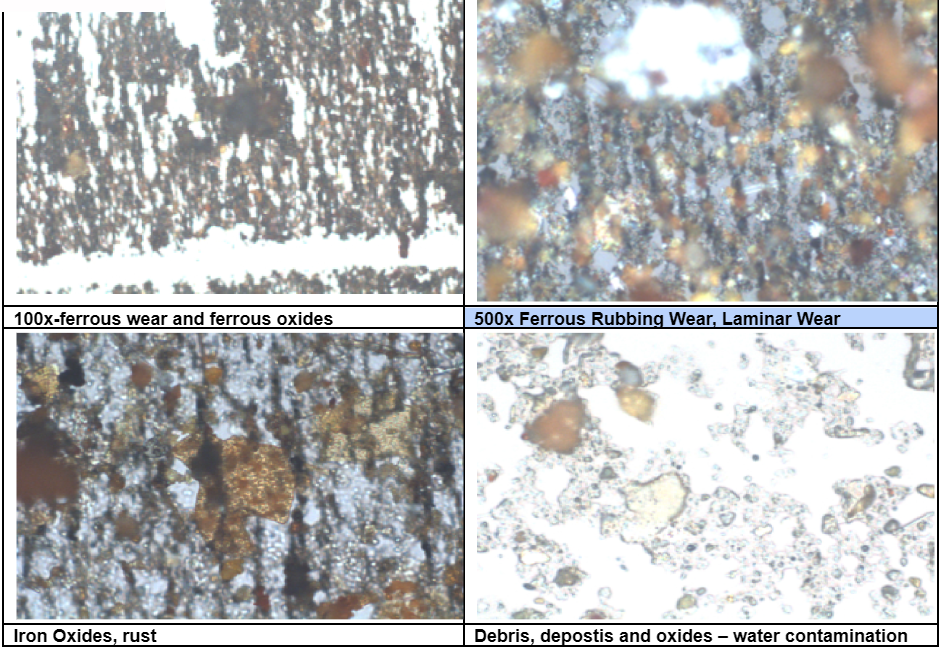

Test results have come back indicating a severe presence of water contamination at 35%, cooling water contaminants were also detected -45 ppm of Silicon, 78 ppm of Sodium, 18 ppm of Phosphorus. The wear metals had also reported higher with 3203 ppm of Iron and 856 ppm detected of ferrous debris – indicating a mix of both rust iron oxides and ferrous wear. 48 ppm of copper, 832 ppm of Tin and 15 ppm of Nickel were also detected. The source of these metals can vary between corrosive wear to babbitted bearing material. The debris was removed from the filter and observed under a microscope for further examination. What was found was large amount of iron oxides throughout the slide, the filter itself had evidence of rust and appeared to be saturated with water. Indicating a severe presence of water contamination. There was a moderate amount of laminar wear detected – in the ferro graphic images these particles will appear to be shiny in color. Many of the particles observed were confirmed to be rust and corrosion particles because of excessive water contamination present. The filter media was covered in rust conditions have worsened from first sample. (see images in page 2 of report)

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

Images taken of the Filter Media

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

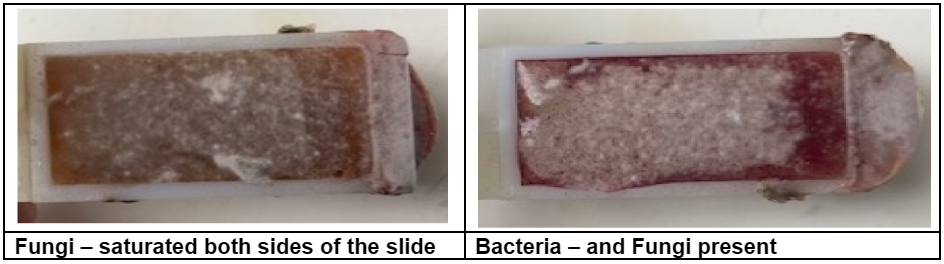

Bacteria Results and Images

Bacteria and Fungi was detected on the slide seen below Fungi was detected at >100,000 CFU/ ml, the slide was saturated with fungi on both side of the slide the presence of fungi is Severe. Bacteria has >100,000 CFU/ ml, it was covered by Fungi but evident on the second image on the right, it was detected below the fungi on the slide. The presence of bacteria and fungi will react with the surfaces of the system resulting in corrosion, fouling and lead to failure.

Make it stand out

Whatever it is, the way you tell your story online can make all the difference.

Observations, Conclusion and Recommendations:

Based upon the overall analysis of the filter media, the unit is exhibiting biological and fungi growth which can lead to corrosion, fouling, improper lubrication regime. Suggest checking the source of cooling water contamination as this is causing the lubricant to have biological growth. Suggest draining the oil from the system and treat/remove the biological matter with a biocide/fungicide, and then refill the unit with new oil after treatment. The presence of water levels are 35% which exceeds OEM specifications of 500 ppm of water. Do not treat the current lubricant in the system with any type of biocide or fungicide as this can result in further problems in the system and can lead to failure. Consult with Lubricant OEM to identify a biocide/fungicide that is compatible with the fluid in use. Corrosion is evident due to water, bacteria and fungi contamination. While wear metals were found to be more corrosive, wear was found to be moderate. Action should be taken to treat the bacteria and fungi to prevent any mechanical failure in the future. Take another sample within two to three months after maintenance has been completed. This is to verify the removal of bacteria and fungi and ensure there is no presence of water or corrosion.